Indirect Heated Calorifiers Suppliers

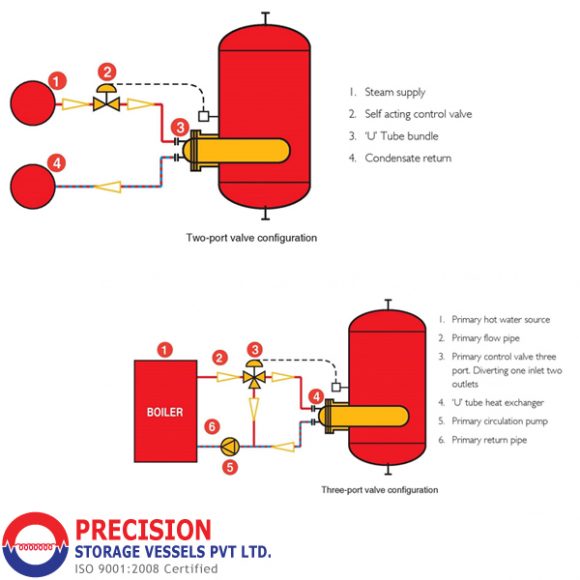

Indirect Heated Storage calorifiers are one of the easiest method of generating hot water for both domestic and industrial applications. Storage calorifiers are installed in hospitals, hotels, sports centers and general residential buildings. PRECISION Calorifiers can be used in sites where a dedicated plant producing steam for laundry or hot water boiler is available.

Storage Calorifier

Storage calorifers are sized to meet the peak demand period with recovery periods varying from one to four hours.

Advantages

- Electric power is not required, hence no big investments in Transformer etc.

- Heating coil duty is high.

- No frequent shutdown due to short circuit etc.

- No need of higher inventory electric spares.

ASME Code construction:- All tanks are constructed in accordance with ASME code section IV.Stamped and labeled for 125 PSI (8.6 BAR) Standard. Precision also design High Capacity Water Heaters / Calorifiers as per British Standard BS 853:1996 or BS 5500:1997 or in accordance with Art 3.3 of the European Directive EEC/97/23 for pressure equipment. Hot Water Indirect KW Shell Material Configuration Capacity.

Copper Coat

Internally surfaces are first grit blasted and cleaned to a white metal finish and then, 100% pure solid copper is sprayed (by metallization process) uniformly in the tank. Once the tank surface is cooled, two coat of precision coat (polymerized coating) is applied to all internal surfaces above the copper coated tank. The tank are then forced cured at 95°C to form a glossy lining unaffected by thermal shock from 6°C to 100°C.

Precision coat is approved by US department of agriculture and with NSF/61 certification for drinking water.

Standard – Shells

Steel SA516 Gr-70

Coating FDA approved Precision coat material

Copper lined vessel

It is uneconomical to manufacture pressure vessel with copper. To make it economical pressure vessels are Manufactured in carbon steel, as per required thickness and then lined with Copper sheets. Precision use 1.2 to 1.6 mm (above 5000 liter 1.6 mm) thick copper sheet which are tack welded to carbon steel shell and Further pulled back by vacuum, so that copper sheet is intact with carbon steel shell. Anti vacuum valve is fitted with all copper lined shells as standard to prevent vacuum (partial /full) that occurs during drain or due to unusual operating conditions..

Standard – Shells

Steel SA516 Gr-70

Copper BS2870-C106