Mineral fiber insulation is either fiber glass or rock wool. Both are inorganic. The raw materials — glass, rock, or slag — are melted and spun or blown into noncombustible blankets, which are then processed into finished insulation. For use in residential or light commercial construction, insulation is supplied in either batts, blankets, or blowing wool (for pneumatic installation). Mineral fiber insulation was first produced in 1840 in Wales. The first plant in the United States went into operation in 1875, manufacturing insulation from the iron slag by-product of gun manufacturing. For approximately 50 years, loose fill insulation, which was installed by hand, was the only mineral fiber insulation product. In the 1920s, blowing wool and pneumatic application were developed, soon followed by the introduction of batts and blankets. Fiber glass joined the mineral insulation family in the mid-1930s. Fiber glass is composed of specially formulated blends of sand, other mineral ingredients, and recycled content called glass cullet. Through the years, manufacturing technology has steadily advanced. Manufacturers now have close control of fiber diameter and length, binder content and distribution, density, resiliency, dimensions, and thermal properties. Also, constant monitoring and inspection and frequent testing ensure consistent quality of the finished product.

Mineral fiber insulation is either fiber glass or rock wool. Both are inorganic. The raw materials — glass, rock, or slag — are melted and spun or blown into noncombustible blankets, which are then processed into finished insulation. For use in residential or light commercial construction, insulation is supplied in either batts, blankets, or blowing wool (for pneumatic installation). Mineral fiber insulation was first produced in 1840 in Wales. The first plant in the United States went into operation in 1875, manufacturing insulation from the iron slag by-product of gun manufacturing. For approximately 50 years, loose fill insulation, which was installed by hand, was the only mineral fiber insulation product. In the 1920s, blowing wool and pneumatic application were developed, soon followed by the introduction of batts and blankets. Fiber glass joined the mineral insulation family in the mid-1930s. Fiber glass is composed of specially formulated blends of sand, other mineral ingredients, and recycled content called glass cullet. Through the years, manufacturing technology has steadily advanced. Manufacturers now have close control of fiber diameter and length, binder content and distribution, density, resiliency, dimensions, and thermal properties. Also, constant monitoring and inspection and frequent testing ensure consistent quality of the finished product.

BENEFITS

The principal benefit of fiber glass insulation is that it reduces energy consumption in both winter and summer, and this helps reduce heating and cooling costs. The exact amount of savings depends upon several variables — climate, local energy rates, and the design and construction of home. Higher R value means greater insulating power.

Thermal Effectiveness – Fiber glass insulation is highly effective in retarding heat flow in all climates during all seasons of the year.

Noncombustible – Fiber glass is noncombustible; however, the vapor retarders on most batts and rolls are flammable and should be covered with gypsum wallboard or other building code-acceptable finish material.

Dimensionally stable – When installed properly, fiber glass insulation will not settle or shrink.

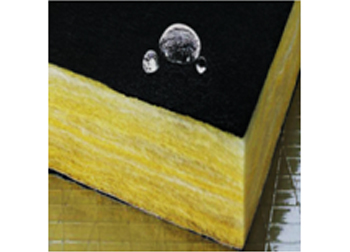

Moisture absorption – Fiber glass will not absorb moisture. This is important because wet insulation is not an efficient insulator.

Noncorrosive – Fiber glass insulation contains no chemicals to corrode steel, copper, or other metal. ASTM C 665 requires that glass fiber insulation be no more corrosive than sterile cotton.

Durability – Because fiber glass is inert, the insulation is permanent. It will last for the life of a home without losing its insulating properties. And it won’t deteriorate over time.

PRODUCTS AVAILABLE

- Blanket Insulation

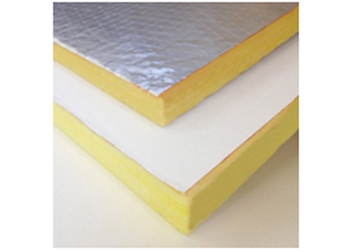

- Board / Slab Insulation

- Pipe Insulation

- Acoustic Insulation