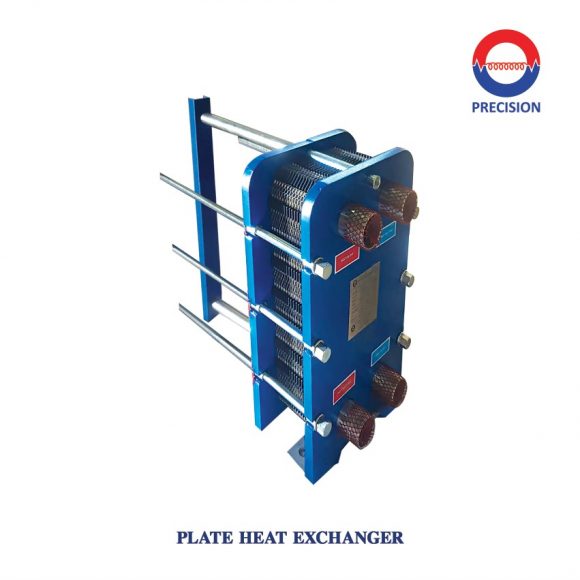

Plate Heat Exchangers

Precision Plate Heat Exchangers are proven to be reliable and highly efficient in heat exchange process. PHE are considered as a best solution for the heat exchange process. PHE can be used even in low temperature difference between the media. PHE are available in different sizes, material grades different plate configuration, different gasket material which makes the PHE suitable for various application. Its easy dismantle construction allows to add more plates in case if we want to increase the duty of PHE.

Construction

Pleat heat exchangers consists of series plate with gasket compressed together in a carbon steel frame. Plates are hanged on the carry bar and kept in line by a guiding bar. length of the carry bar, guiding bar and tightening bolts will change in different models.

Technical Specification :

- Mild Steel powder coated

- Stainless Steel frames

Plates :

- Stainless Steel AISI 304

- Stainless Steel AISI 316

- Stainless Steel AISI 316 L

- Titanium Grade

- Alloy 254 SMO

- Hastelloy C 276

Gasket Material:

- NBR (130˚ C)

- EPDM (150˚ C)

- Viton (180˚ C)

www.precisionstoragevessels.com/

Plate Heat Exchanger – Maintenance and Servicing

- We have trained service personnel to maintain all makes of Plate Heat Exchanger.

- We can do commissioning and re-commissioning of any type heat exchanger.

- Cleaning of plate heat exchangers at its location at site with cleaning detergent.

- Removal of hard scales by using high pressure jet cleaners.

- Cleaning of each plates.

- Replacement of plates if necessary.

- Replacement of bolts and nuts if required.

- Replacement of gaskets.

- Fixing of rubber liners and ring gaskets.

- Assembling of plate package and pressure testing at site

- Performing annual maintenance.

- Trouble shooting of plate heat exchanger for leakage, insufficient capacity, too high pressure drop, cold leakage, gasket failures etc.

- Replacement of insulation and drip tray.

ONDA PLATE HEAT EXCHANGERS

Application range:

- Operating Pressure: up to 25 bar for standard units

- Operating Temperature: up to 170°C for standard units

– higher values on request-

Materials:

- Frame : Carbon Steel, Painted

- Plates : AISI 316L / TITANIUM / AISI304L

- Gaskets : NBR (110 DEG C Max) / EPDM (140 DEG C Max) / VITON

- Tightening Bolts : Galvanized Steel

- Connections : AISI 304/ AISI 316 / PVC / POM-C

Certifications :

- ISO 9001 Vision 2000

- P.E.D (European Pressure Directive 97/23 CE)

- ASME

Optional Accessories:

- Insulation

- Tie rod protection

- Drip tray

- Ratchet spanner

- Protection shield